Have any questions?

+44 1234 567 890

Making quality measurable

Optical 3D measurement technology for quality inspection in production

Optical 3D measurement technology is used in various applications due to its precision, speed and versatility. It enables accurate measurements of complex surfaces without touching the object, which prevents damage. This technology is used in quality control, reverse engineering, product development and more. Through its automation capability and digital data acquisition, it helps to increase efficiency and reduce costs by detecting defects early and improving production performance.

With its customized confocal microscopy technology, Twip optical solutions offers a highly effective method for the fast and precise capture of three-dimensional surfaces in a wide range of industries.

Confocal microscopy technology from twip optical solutions

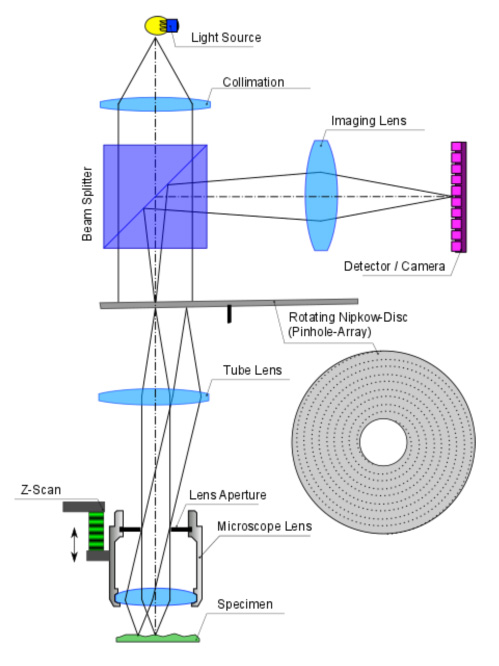

The 3D detection of surfaces with sub-micrometer resolution. - A point light source is imaged onto the object to be measured and the illuminated object point is projected onto a detector via a very small pinhole aperture. The exact position of the object is determined by evaluating the intensity curve in the confocal image stack.

The innovative measuring system from twip optical solutions uses a rotating microlens disk to enable reliable measurements on highly absorbent or weakly reflective objects.

Advantages

High axial resolution

Determination of 3D topography with a resolution of up to a few nanometers

Independent of surface properties

Measurement of all surfaces, whether reflective or rough, regardless of color or reflectance

Fast measurement and simple evaluation

Measurement speed correlates with the resolution

Low resolution and magnification enable fast measurements

High resolution can still be implemented quickly due to smaller measuring ranges in the axial direction.

Up to 1.3 million measuring points in 3 seconds

Special features of confocal microscopy

Special setup leads to "confocal filtering"

The image is only bright in the focal plane

Several images are captured by a height scan

The maximum brightness defines the object position

Welche Möglichkeiten ergeben sich durch die konfokale Mikroskopie

Confocal microscopy plays a crucial role in quality assurance in production as well as in research and development. It is widely used in a variety of industries, including aerospace, automotive, mechanical engineering, plastics, electronics and many others. The versatility of this technology enables precise analyses and measurements that make a significant contribution to product and process improvement in these areas.

We will be happy to assist you and provide you with advice and support

Get in touch with us!